pacakging leak testing

Package Leak Tester

Food & Pharmaceutical Packaging Integrity

About

Package Leak Test

The integrity of packaging is paramount. Whether safeguarding life-saving pharmaceuticals, ensuring food freshness, or protecting sterile medical devices, a compromised seal can lead to product spoilage, safety hazards, regulatory failures, and costly recalls. This is where a reliable package leak tester becomes an indispensable tool in quality control. Understanding the principles, methods, and standards governing leak detection is critical for professionals across packaging, medical, pharmaceutical, and food industries.

Let’s explore the the core technologies, relevant standards like ASTM F2096, ASTM F2338, ASTM F1140, ASTM D3078, and USP 1207, and best practices for effective package leak detection.

Understanding Package Leak Testing

Why Package Leak Detection Matters

Leaks in packaging can lead to contamination, spoilage, or compromised sterility. For instance, a food package leak test prevents microbial ingress, while pharmaceutical package leak detection ensures sterile barriers in blister packs. Early detection reduces waste, recalls, and reputational damage.

A leak, no matter how small, breaches the protective barrier of a package. Consequences include:

01

Loss of Sterility

Critical for medical devices and pharmaceuticals, allowing microbial ingress.

02

Product Degradation

Exposure to oxygen, moisture, or contaminants spoils food, drugs, and sensitive products.

03

Reduced Shelf Life

Accelerated deterioration leading to waste and customer dissatisfaction.

04

Regulatory Non-Compliance

Failure to meet stringent FDA, EMA, ISO 11607, or USP requirements.

05

Brand Damage & Recalls

Loss of consumer trust and significant financial impact.

A package leak tester is specifically designed to identify these breaches, either destructively or non-destructively, depending on the method and application. Choosing the right test method depends on package type (rigid, flexible, porous), required sensitivity, production environment (lab, offline, online), and governing standards.

Package Leak Detectio

Common Methods for Package Leak Testing

Several established methods exist, each with distinct principles, advantages, and limitations. Key standards define these procedures.

1. Bubble Leak Test – ASTM F2096 & ASTM D3078

The bubble emission method (also called internal pressurization or vacuum bubble test) detects gross leaks in flexible packages such as pouches and trays.

- ASTM F2096 uses internal air pressurization underwater. The package is submerged, inflated, and inspected for bubble streams.

- ASTM D3078 involves placing packages in a vacuum chamber filled with water. Under reduced pressure, leaks appear as visible bubbles.

These methods are simple and effective for flexible packaging, but they are destructive and best suited for laboratory environments.

2. Vacuum Decay Method – ASTM F2338

The vacuum decay package leak tester is a non-destructive method. The package is placed in a chamber where vacuum is applied. Sensitive pressure transducers detect minute changes in pressure that indicate leaks.

This method:

- Complies with USP 1207 guidelines for deterministic testing.

- Detects leaks invisible to the naked eye.

- Works for rigid and semi-rigid packaging (e.g., blister packs, trays, vials).

3. Burst and Creep Testing – ASTM F1140

ASTM F1140 evaluates seal strength and package failure pressure. Packages are internally pressurized until they burst, or pressure is held over time to check seal durability. These tests are particularly important for medical device packaging that must withstand sterilization and transport stresses.

Applications of Package Leak Testers

Food manufacturers rely on food package leak tests to ensure extended shelf life and safety. Modified atmosphere packaging (MAP), vacuum-sealed products, and flexible pouches require routine leak testing to prevent oxygen ingress and spoilage.

– Food Packaging Leak Detection

Pharmaceutical blister packs, vials, and syringes must remain sterile until point of use. Leak test procedures for blister packaging are guided by USP 1207 and ASTM F2338, which recommend non-destructive, deterministic testing methods like vacuum decay.

– Pharmaceutical Package Leak Detection

Sterile barrier systems for medical devices are tested under ASTM F2096 and ASTM F2338. Detecting even micro-leaks ensures compliance with FDA and ISO requirements.

– Medical Device Packaging

From daily chemicals to adhesives and beverages, flexible packaging leak detection prevents product loss, contamination, and poor consumer experience.

– Flexible Packaging Integrity

Blister Packaging Leak Test

Guidelines for Leak Testing Blister Packaging

Blister packaging is widely used in pharmaceuticals but is particularly vulnerable at the seal junction between foil and plastic.

- ASTM F2338 (vacuum decay) provides a non-destructive, highly sensitive method.

- ASTM F1140 (burst/creep testing) evaluates seal strength.

- USP 1207 encourages deterministic methods over probabilistic approaches like dye ingress.

By following these guidelines, manufacturers ensure compliance while minimizing waste.

Best leak tester for packaging

Recommended Solutions: Cell Instruments Leak Testers

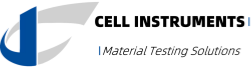

Cell Instruments provides a comprehensive portfolio of package leak testers designed to meet international testing standards and the diverse needs of packaging integrity verification. Each instrument is engineered for precision, ease of operation, and compliance with ASTM and USP 1207 guidelines.

01

LT Leak Tester – Bubble Emission Method (ASTM D3078)

The LT Leak Tester is purpose-built for bubble leak testing of flexible packaging. By submerging a sample in water under vacuum, it allows operators to observe air bubble streams that indicate leaks.

- Applications: Food packaging pouches, daily chemical packaging, medical device trays.

- Advantages:

- Simple operation with visible results.

- High sensitivity for gross leak detection.

- Conforms to ASTM D3078 requirements.

- Best For: Routine quality control labs where destructive testing is acceptable.

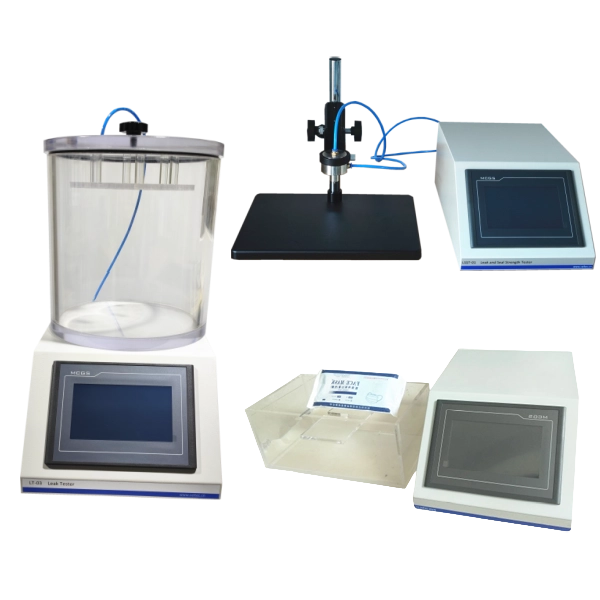

02

MLT-01 Vacuum Decay Leak Tester – Non-Destructive Method (ASTM F2338, USP 1207)

The MLT-01 is a vacuum decay package leak tester ideal for pharmaceutical and medical device packaging that requires deterministic, non-destructive testing.

- Applications: Blister packs, syringes, vials, sterile barrier systems.

- Advantages:

- Non-destructive testing saves samples for further evaluation.

- Complies with ASTM F2338 and USP 1207 deterministic testing requirements.

- Sensitive pressure transducers detect micro-leaks invisible to bubble methods.

- Suitable for both rigid and semi-rigid packaging.

- Best For: Pharmaceutical and medical industries where sterility assurance is critical.

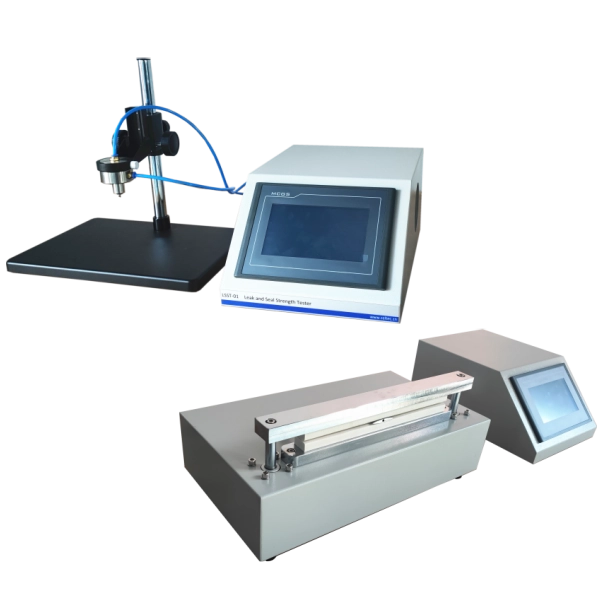

01

LSST-01 Pouch Burst Tester – Seal Strength Testing (ASTM F1140)

The LSST-01 evaluates the seal strength of flexible and semi-rigid packaging through burst, creep, and creep-to-failure tests.

- Applications: Medical device pouches, foil-sealed blister packs, pharmaceutical trays.

- Advantages:

- Measures maximum burst pressure and seal integrity.

- Performs creep testing for real-world transport and sterilization stress.

- Conforms to ASTM F1140 standards.

- Best For: Manufacturers needing to verify sealing parameters and prevent packaging failures in production or logistics.

02

GLT-01 Gross Leak Tester – High-Speed Leak Detection

The GLT-01 is designed for rapid detection of large leaks in packaging systems. Using pressurization or immersion principles, it identifies defects that compromise package integrity.

Applications: Trays, flexible packs, large-volume pouches.

Advantages:

Detects gross leaks quickly for large-scale packaging runs.

Can test multiple samples simultaneously.

Provides a cost-effective tool for in-process quality control.

Best For: Food, beverage, and chemical packaging where production efficiency requires fast and reliable gross leak detection.

Built with reliability at the core, our instruments deliver accurate and repeatable results, and we further strengthen customer confidence by offering customized solutions to address special testing requirements or automation needs.

– Cell Instruments

Frequently Asked Questions about Bekk Smoothness Test

1. What is a package leak tester and why is it important?

A package leak tester is an instrument used to detect leaks in packaging, ensuring product safety, extended shelf life, and regulatory compliance. Even small leaks can lead to contamination, spoilage, or loss of sterility, which is why leak testing is critical in food, pharmaceutical, and medical packaging.

2. What are the most common test methods for package leak detection?

The most widely used methods include the bubble emission test (ASTM F2096, ASTM D3078), the vacuum decay method (ASTM F2338, USP 1207), and burst/creep testing (ASTM F1140). Each method has specific applications depending on the packaging material and industry requirements.

3. Which leak test is best for blister packaging?

For blister packaging, deterministic and non-destructive methods like the vacuum decay leak tester for packaging are recommended, as outlined in ASTM F2338 and USP 1207. These methods provide higher sensitivity and preserve samples for further evaluation.

4. How does a vacuum leak tester for packaging work?

In vacuum decay testing, the package is placed in a sealed chamber where vacuum is applied. Sensitive pressure transducers monitor for changes in pressure, which indicate leaks. This method is fast, reliable, and fully compliant with USP 1207 guidelines.

5. What standards should be followed for pharmaceutical package leak detection?

Pharmaceutical manufacturers should follow USP 1207, which emphasizes deterministic methods like vacuum decay testing. In addition, ASTM F2338 provides the reference procedure for non-destructive detection of leaks in pharmaceutical blister packs, syringes, and vials.

6. What is the difference between destructive and non-destructive package leak testing?

Destructive methods, such as bubble emission (ASTM F2096, D3078), require opening or damaging the package, making them suitable for lab-based testing. Non-destructive methods, like vacuum decay (ASTM F2338), preserve the package, making them ideal for pharmaceutical and medical packaging where samples are costly or sterile.

7. Can package leak testers be used for food packaging?

Yes. Food package leak tests ensure that modified atmosphere packaging (MAP), vacuum-sealed bags, and pouches remain airtight to preserve freshness and prevent oxygen ingress. Both bubble emission and vacuum decay methods are widely applied in the food industry.

8. What is the leak test procedure for blister packs?

The leak test for blister packaging typically follows ASTM F2338, where the blister pack is tested in a vacuum chamber to detect micro-leaks. For gross leaks or seal strength evaluation, ASTM F1140 burst and creep tests may also be applied.

9. Does Cell Instruments provide customized leak testers?

Yes. Beyond standard models such as the LT Leak Tester, MLT-01 Vacuum Decay Leak Tester, LSST-01 Pouch Burst Tester, and GLT-01 Gross Leak Tester, Cell Instruments specializes in customizing leak detection systems to meet specific material, packaging, or automation requirements.

10. How can I choose the right leak tester for my application?

The choice depends on your package type (rigid, semi-rigid, or flexible), your industry (food, pharmaceutical, or medical), and your regulatory requirements. For example, food packaging often uses bubble emission tests, while pharmaceuticals typically require vacuum decay testing under USP 1207. The experts at Cell Instruments can recommend the most suitable solution based on your needs.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985